- GF/ SF - Tejas, Opp Hotel Prasadalay, Shukrawar Peth, Pune - 411002

- +91 90 2132 2132

Warehouse 5S: A Lean Strategy for Smarter Logistics

Warehouse 5S might sound like just another buzzword, but it is one of the smartest ways to be more efficient with logistics. Warehouse management is essential, especially with supply chains moving faster than ever. And if it is not organized? Things get messy fast: delays, lost inventory, unhappy customers, you name it.

That’s one of the reasons so many logistics professionals have adopted 5S warehouse management. It is a lean, straightforward system of sorting, organizing, cleaning, and eliminating waste. No matter if you are just starting to optimize your warehouse or you are fine-tuning an established operation, 5S provides a good foundation for operating a smoother, faster, and more efficient warehouse.

What is Warehouse 5S and Why Does It Matter in Logistics

Let’s face it, warehouses can get chaotic fast. That is exactly where Warehouse 5S comes into play. It is a simple yet effective lean management approach that helps you get organized, maintain an efficient flow, and create a safe environment. Although developed in Japan, the 5S methodology has five core steps.

Each of these steps is crucial for achieving a clean and organized workspace where every item has its place and a purpose.

So, why should logistics and fulfillment centers care? Because when you implement 5S warehouse management, you can expect:

-

Quicker order picking

-

Fewer misplaced items

-

Smarter use of space

-

More team accountability

In a nutshell, it’s a solid base for achieving lean warehouse management that actually works. Also, to know more about Warehouse Throughput strategies, visit here.

The 5S Principles

So what are these five magical steps? Let’s break them down in layman’s terms:

-

Sort (Seiri) : Remove any unnecessary items from the workspace; only keep items that are absolutely necessary. Everything else? Out it goes.

-

Set in Order (Seiton): Once you have sorted the space, arrange the items that are left in a manner that everything is organized and is easy to find, as well as easy to put back into order. Think bins, labels, and logical layout.

-

Shine (Seiso): Clean the area regularly. Not just for appearance, but to address any issues early in the process (for example, leaky pallets or broken tools).

-

Standardize (Seiketsu): Create a standardized way of executing tasks. Same layout, same steps, same results every time.

-

Sustain (Shitsuke): Make things stick. Train your team, conduct audits, and hold everyone accountable.

It is not just about tidying up; it’s about creating a warehouse that practically runs itself.

The Real Benefits of 5S in Your Warehouse

You might be thinking, "Ok, this sounds good, but is it worth it?" Absolutely. Here's why 5S warehouse management is a win-win situation for everyone:

-

Efficiency goes through the roof: When everything has a designated space, your team spends less time searching for items and more time getting things done.

-

It looks and feels professional: A clean, organized space can raise morale and impress clients and auditors.

-

Fewer mistakes: Clear labels and organized layouts reduce confusion and minimize shipping errors.

-

Training gets easier: New team members can become productive more quickly because you have a predictable and standardized setup.

Simply put, the 5S benefits in a warehouse directly impact your bottom line and your customer satisfaction.

5S Warehouse Examples You Can Steal Today

You do not have to do it all again. Here are five 5S warehouse examples we have seen work wonders:

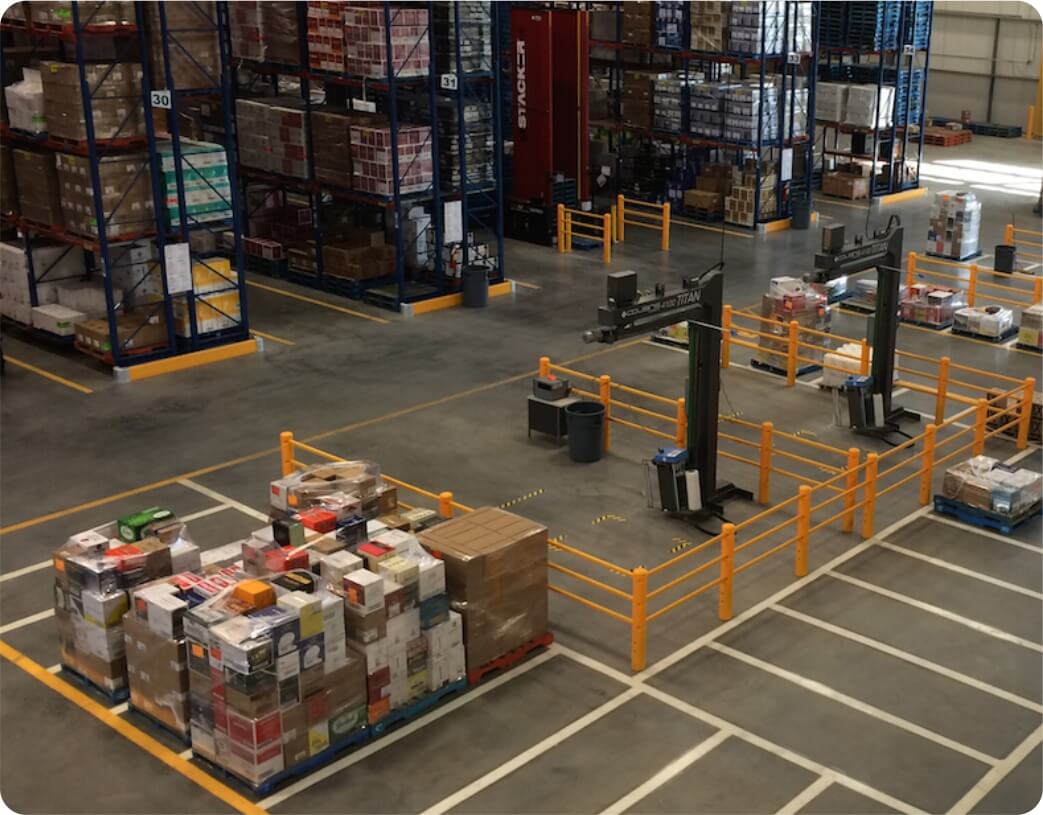

- Color-coded zones: Use colors to designate areas for picking, packing, returns, etc. This makes it easy for your team to find things.

- Shadow boards: Outline tools on pegboards so nothing gets forgotten.

- Barcode labeling: Label all shelves, bins, and racks with scannable codes to save time in inventory management and reporting.

- Floor tape and signs: Mark walkways, pallet locations, and forklift lanes for no confusion and clear safety measures.

These are easy wins that bring serious structure to your warehouse.

Build Your Own 5S Warehouse Checklist

So, are you good to go? Begin with a 5S warehouse checklist so nothing gets overlooked. Here is a basic 5S warehouse checklist you can modify as needed:

- Clear out outdated inventory or unused items.

- Assign places for tools, supplies, and equipment.

- Schedule a daily or weekly cleaning routine.

- Add labels, signs, and color codes.

- Develop step-by-step Standard Operating Procedures (SOPs) for simple tasks.

- Run monthly 5S audits.

- Offer refresher training regularly.

Having a checklist makes it easier to stay consistent and keep everyone on the same page.

Supercharge 5S with a Warehouse Management System (WMS)

Ready to elevate your 5S initiatives? Leverage a smart Warehouse Management System (WMS).

Here’s how a WMS helps:

- Track everything in real-time - no more guessing what’s where

- Automate picking and packing tasks

- Monitor team performance and warehouse KPIs (Key Performance Indicators)

- Reduce human error with barcode and RFID integration

When your 5S setup and WMS work together, you get a fully optimized, tech-enabled warehouse that’s ready to scale.

Wrapping It Up: Why Warehouse 5S Is a No-Brainer

Let's be honest, there are no magic buttons for perfect operations. But Warehouse 5S is about as good as it gets in terms of preparing your team for success.

It helps you clean up the mess, organize the chaos, and develop a system that actually sticks. Pair it with tools like a WMS, and you have a warehouse that is lean, mean, and ready to deliver.

Thinking about 5S warehouse implementation? Let Velocity Express help you build a system that saves you time, saves your costs, and keeps your logistics engine running like clockwork.

Frequently Asked Questions

-

What is 5S in a warehouse?5S in a warehouse is a lean management method based on five concepts, or principles: Sort, Set in Order, Shine, Standardize, and Sustain to improve warehouse organization, safety, and efficiency.

-

How to 5S a warehouse?To 5S a warehouse, you would first Sort (remove unnecessary items), Set in Order (tools and inventory), Shine (clean), Standardize (procedures to follow), and Sustain (have discipline to continually follow checklists and maintain procedures).

-

How to implement 5S in a warehouse?Implementing the 5S in warehouse management involves employee training, 5S checklist creation, labelling purposes, documenting cleaning schedules, and conducting 5S audits regularly for continuous improvement.

-

How often should 5S audits be conducted in a warehouse?5S audits should be performed weekly or on a monthly basis, depending on the size and complexity of the warehouse. Regular audits support improved efficiency for the warehouse and lean warehouse management practices.

-

Is 5S suitable for small businesses?Yes, 5S warehouse management can be especially beneficial for small businesses. It reduces waste, saves money, and increases efficiency. 5S warehouse management practices make managing space easier and the operation of the business more efficient.