- GF/ SF - Tejas, Opp Hotel Prasadalay, Shukrawar Peth, Pune - 411002

- +91 90 2132 2132

What is Economic Order Quantity (EOQ) in Inventory Control?

If you are running a business, economic order quantity (EOQ) in Inventory Control helps you order the right amount of inventory. Order too much, and you tie up working capital in storage; order too little, and stock may run out. This is where EOQ, the economic order quantity model, helps you strike the right balance: it is almost like a magic formula to help the business maintain a perfect balance.

By calculating the ideal order size such that the minimum cost is incurred while operations are kept flowing. However, how does it actually function, and why is it so important to inventory control?

Let’s dive in.

What is Economic Order Quantity (EOQ)?

The concept of Economic Order Quantity (EOQ) deals with stock optimization and inventory decisions based on calculated optimal order quantities. It is said that EOQ is the number of units that a business should purchase in order to minimize the total costs involved in inventory, that is, the costs of ordering and holding storage. Ordering costs arise whenever an order is placed, while holding costs include storage costs, insurance, and the depreciation of unsold inventory.

Balancing these two expenses is done through the EOQ model as a solution against overstocking and ordering too frequently. However, an important limitation of this model is that it assumes steady demand over time, which is not often true for businesses in rapidly changing markets.

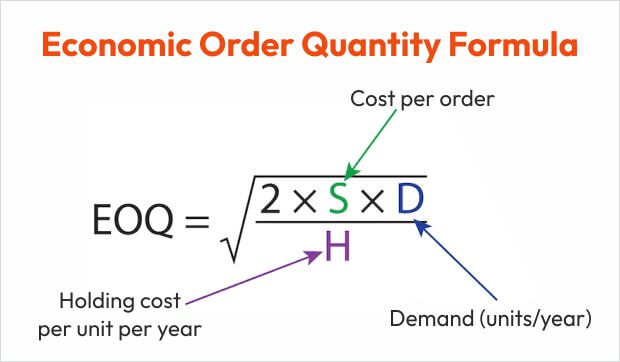

EOQ Formula

The EOQ formula is expressed as:

Where :

- D = Demand (units/year)

- S = Cost per order

- H = Holding cost per unit per year

By applying the above formula, the order quantity can be determined in such a way that the total cost of inventory will be minimized.

Example of How to Use Economic Order Quantity (EOQ)

EOQ determines what quantity of inventory must be ordered based on demand, ordering cost, and holding cost. This is a factor that helps a business run very economically in the management of inventory, as well as the costs that arise from either overstocking or frequent re-ordering.

Example:

A bookstore sells a very popular novel that could sell as many as 5,000 copies a year. The holding cost for each book in stock is ₹10 per year, while preparing an order incurs a cost of ₹50.

To find the Economic Order Quantity (EOQ), the formula considers:

- The yearly demand for a product (how many units are sold in a year)

- The order cost (how much the company spends every time it places an order)

- The holding per unit cost (the cost of storing one unit for one year)

Substituting these values in the EOQ formula, the bookstore finds that the optimal order quantity is 224 books per order. It is clear that to minimize costs and keep inventory at an effective level, the bookstore must place an order for 224 books at a time.

Moreover, the reorder point is calculated by how quickly books are selling, together with the duration of time it takes to receive a new order. This is to ensure that fresh supplies are ordered before stocks run out.

Key Benefits of Implementing Economic Order Quantity (EOQ)

The Economic Order Quantity (EOQ) for businesses is a magic tool for those who keep inventory for the manufacture, resale, or internal consumption. EOQ will, by analyzing your order quantity, give you a solution that streamlines operations, thereby achieving as low a cost as possible while improving efficiency. Some of the benefits include:

-

Balanced Inventory Control

EOQ specifies orders of the right number of stock orders so that excess inventory does not pile up in the warehouses. Hence it plays a role in fulfilling orders efficiently, increasing the degree of customer satisfaction, and improving the sales performance.

-

Avoid Inventory Gaps

Businesses can avoid stockouts during peak periods by utilizing EOQ calculations and demand forecasts. These strategies help keep the operations running smoothly while ensuring no sales opportunities are lost.

-

Reduces Warehousing Expenses

One can avoid incurring unnecessary excess storage costs by ordering the optimal quantity. Such costs include warehousing, security, insurance as well as other utility costs. All these will result in a significant saving for better resource allocation.

-

Reduces Product Wastage

Well-thought-out EOQ strategy ensures that businesses can avoid the presence of obsolete and expired inventories, especially found useful by industries where perishable goods can have dead stock and result in bearing heavy financial losses.

-

Improved Financial Outcomes

EOQ is a financial optimization tool involving inventory management that reduces unnecessary costs, which includes lower storage costs and smaller stockouts reflected in cash flow and higher profitability.

Importance of EOQ

Economic order quantity is important for businesses to efficiently manage inventory and avoid problems of overstocking in times of low demand and understocking in times of high demand. Both of these situations result in missed opportunities. In the competitive world of ecommerce, efficient inventory management can be the key to success.

Having made extensive use of the EOQ, it would be able to meet better customer demand, reduce lead time, and minimize ordering and holding costs. This will result in enhanced customer satisfaction and profitability, giving a more efficient supply chain.

Making sure that your economic order quantity is a competitive edge in a world where demand is moving very quickly. It enables quick responses to market fluctuations and maintains a lean, agile inventory system.

EOQ Assumptions and Limitations

EOQ, though extremely effective, suffers certain limitations and assumptions that may not be in a position to meet the real-world situations:

- Constant Demand: The EOQ performs the best when the demand remains the same over time.

- Immediate Replenishment: The model is set in a way that it immediately restocks after an order has been placed.

- Fixed Costs: EOQ calculations rely on fixed costs for ordering, holding, and per-unit costs, which may fluctuate in practice.

When to Use EOQ?

EOQ is best used with a predictive demand and steady turnover. On the other hand, in businesses where demand may be sporadic, such seasonal factors might require adjusting the approach to the dynamic management of inventory.

A Business is able to make decisions that improve its efficiency, minimize wastage, and maximize profitability when it aligns EOQ with the essence of inventory systems.

Final Thoughts

The Economic Order Quantity is a strong formula for your business, a way to manage inventory and cut costs while maintaining product availability. EOQ balances the ordering cost against holding cost to prevent potential overstocking and total stockouts, creating a cost-friendly working environment for profitability.

It is most effective in stable demand conditions, but businesses can change it around to meet their needs. The application of EOQ to the inventory strategy creates better cash flow, reduced waste, and even greater customer satisfaction- this becomes a critical practice for future growth.