- GF/ SF - Tejas, Opp Hotel Prasadalay, Shukrawar Peth, Pune - 411002

- +91 90 2132 2132

Sorting Centers: The Backbone of Ecommerce Logistics

Imagine a bustling hub where thousands of packages from all over the world converge, only to be swiftly sorted and sent off to their final destinations - sometimes in mere hours. Sorting centers are the unsung heroes leading every modern logistical operation; they make what looks like an entity organized loosely into a seamless operation.

So, what exactly happens out of view in such a setting? How is it possible to process and route millions of parcels every day? The answer lies in advanced technologies and consistency, which keep e-commerce and courier services on their feet so that your next delivery will always be there, right on time.

What is a Sorting Center?

A Sorting center is the backstage of the delivery world - the action happens here before packages are sent to your doorstep. There is a large, highly technical system where parcels from all over are quickly organized and sent to their rightful path. Sort each envelope based on size, from small to oversized, so that it can be placed where it needs to go, according to its delivery speed, size, and priority.

Sorting centers are truly the heart of logistics, processing millions of packages in lightening speed according to their size, priority, and destination. These hubs just really ensure the next order purchased online does not take too long to reach you.

These sorting centers help in reducing errors, streamlining the process, and saving precious time by sorting the packages according to their size, priority, and destination. The end result is faster delivery, reduced costs, and a more efficient logistics operation. In other words, sorting centers make the whole supply chain faster, smarter, and reliable.

An Overview of the Role of Sorting Centers in E-Commerce Logistics

-

Receiving Packages

Intake: Various carriers deliver packages to the sorting center, including local delivery vehicles, regional warehouses, and direct shipments.

Scanning and Identification: These packages are scanned with either a barcode or radio frequency identification (RFID) for tracking information, such as the package's destination, size, and priority. That information is then sent to the center's management system for accurate tracking.

-

Sorting Packages

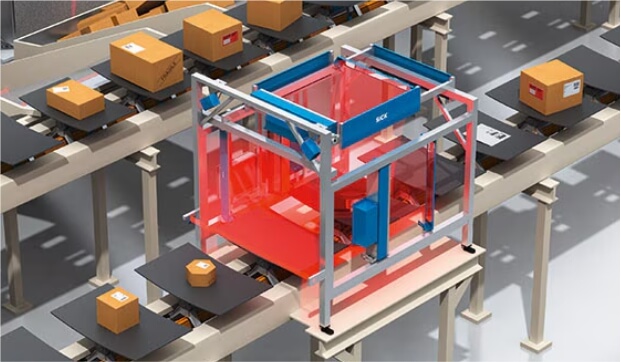

Automated Sorting: Cross-belt sorters are modern technologies that sort packages according to predetermined conditions in no time. These systems distribute and guide products along different conveyor systems to their final destinations.

Manual Sorting: While much of the sorting will be done automatically, good manual sorting has also to be in place to monitor operations on site. This supervision will attend to all those sorting irregularities and will ensure the correct redirecting of packages to their destination.

-

Dispatching Packages

Consolidation: The ordered packages arrive at the center and are sorted based on their final destination to improve the routes and methods for deliveries.

Loading: The next step is to load the items for transport, by delivery vans, trucks, or drones, for a final delivery.

Tracking: The packages are tracked throughout dispatching to provide timely status updates to customers and logistics agents.

-

Impact on Delivery Speed and Cost

Efficiency: Optimized sorting minimizes bottlenecks that lead to negligible or no handling time and thus decreases the order fulfillment time.

Cost Reduction: Save operations cost and bring about high efficiency overall of the supply chain as reduced errors and delays with optimized sorting.

Tech-Driven Sorting: A New Era in E-Commerce Logistics

Sorting centres aren't a new phenomenon. But the hallmark of today's sorting centres is the use of technology to increase speed and accuracy. What are the technologies that are driving the new-age sorting centers? Let's have a look:

-

Automated conveyor belts and sorting machines

Everything in a modern sorting center revolves around conveyor belts outfitted with sensors and diverters. Cross-belt sorters are automated in taking the assigned articles according to size, destination, or priority, thereby providing easy and fast operational procedures to enhance speed and accuracy. Everything gets to where it's going - fast.

-

Barcode and RFID scanning systems

Barcodes and RFID tags are instruments that track packages on every level of the sorting process. The scanners read scanned data very quickly during package induction into the system to ensure that each package is identified, routed, and tracked properly in real time. This technology minimizes mistakes and maintains synchronization throughout the entire process so that no package loses its way.

-

AI and Machine Learning for package routing

AI: AI-backed sorting processes have become technically intelligent. Real-time decisions with regards to optimization of routes are taken based on past data learned by these systems. By analyzing data constantly, these systems ensure packages take the fastest path, adapting to changes as they go.

Machine learning: The machine learning model learns on the historical data and modifies its future system behavior. It can identify the peak intervals and adjust the routing strategies as well as improve the sorting algorithms accordingly.

-

Robotics and Drone Technology

Robotics: Various activities are performed using robots, including picking, packing, and sorting within sorting centers. The automated robotic arms allow other handling techniques for delicate or heavy loads, bringing about faster and precise operations.

Drone Technology: Drones are used in sorting houses for either inventory management or internal transport of packages and in external last-mile delivery. Drones have the capability of flying autonomously, carrying packages between designated points within the warehouse.

-

Smart tracking and Real-time updates for customers

Smart Tracking: IoT-enabled tracking systems provide real-time monitoring of packages throughout the sorting process. Information is sent from RFID tags, GPS devices, and other sensors to a centralized platform, granting visibility to the package journey.

Real-time Updates: Notification is provided in real-time for every stage in transit and finally by sending invoices to customers or logistics managers. They may include changes in expected delivery, delays, or any issues faced during transit.

The Journey of a Package - Inside a Sorting Centre

Sorting centres are a world of their own. If you visit a sorting centre, you will witness rapid movement everywhere. You would see packages being moved from one area to the other, people scanning codes, trucks being loaded with packages at one corner, a group of people meticulously noting down things. In a nutshell, it is an organized chaos that powers the last leg of the logistics management process. Here's a detailed explanation of what actually happens in a sorting centre.

-

Receiving packages from different locations

Packages are being brought into the sorting facility from different locations, such as trucks, containers, or smaller vehicles, and there they are unloaded onto receiving conveyor belts or staging areas. On arrival, the goods are thoroughly inspected to make sure they match the order information and to check for any damage that may have occurred during transit.

-

Sorting based on size, destination, and priority

The packages are then sorted according to size, priority, and destination. The mechanism initiates the procedure of package sorting using mechanical techniques and scanning devices like barcode and RFID code scanners. AI algorithms are then used to route packages optimally and efficiently toward their destination. These technologies smoothen the whole sorting process to achieve speed and accuracy while minimizing potential human errors or delays.

-

Quality checks and damage handling

Packages are inspected for both content verification and transit damage detection. If any items are found to be damaged, these are flagged for return or special handling; only intact packages are allowed to go through, maintaining an accurate inventory.

-

Dispatching to delivery hubs

There are now several packages that are sorted out and checked and placed in specific designated vehicles or containers based on their destination and priority. These packages are then delivered to the specific delivery hubs for fast and timely transportation.

The Hidden Challenges: What Sorting Centers Struggle With

Sorting centres bring efficiency in the logistics process. But creating an efficient sorting centre isn't a cakewalk. Sorting centres grapple with challenges and you need to mitigate them to ensure your sorting centres function smoothly. We list down some of the key challenges of sorting centres here.

-

The Handling high-volume shipments, especially during peak seasons

During the regular big holiday time packages, they overflow sorting centers well beyond their normal capacity for parcel processing. This puts pressure not just on the equipment but also on the staff, resulting in a very high chance of errors caused by delays in sorting and slower dispatch times that will harm timely delivery.

-

Delays due to incorrect labeling or damaged packages

Such heavy postponement occurs due to lost, mislabelled, or damaged packages because the relabelling, inspection, or re-packaging takes further detailed time and indeed hampers the whole workflow, causing a slow pace for the entire sorting and delivery operation.

-

Security issues and package loss

Theft, item loss, and untracked packages are security troubles that carry the weight of heavy losses. To safeguard against such risks, sorting centers must, therefore, have high-end surveillance systems and stringent control measures in place to ensure every package is safely handled and tracked.

Final Thoughts

Have you noticed the working efficiency of sorting centers concerning the final customer satisfaction? Indeed, efficient sorting centers are very much part of customer satisfaction, especially regarding fast, accurate, and timely processing of packages.

Sorting centers deploy the most recent technologies, such as automation and AI, along with RFID scanning to reduce errors, optimize delivery routes, and handle higher volumes of work in peak season. All these improvements lead to faster deliveries and real-time updates that help enrich the customer experience.

Looking ahead, the future of sorting technology will involve more automation, AI optimization, and innovations like drones for speedy delivery. These technologies will make sorting centers more efficient with real-time tracking and sustainable practices, therefore being more adaptive to the increasing needs of e-commerce for good customer satisfaction levels.