- GF/ SF - Tejas, Opp Hotel Prasadalay, Shukrawar Peth, Pune - 411002

- +91 90 2132 2132

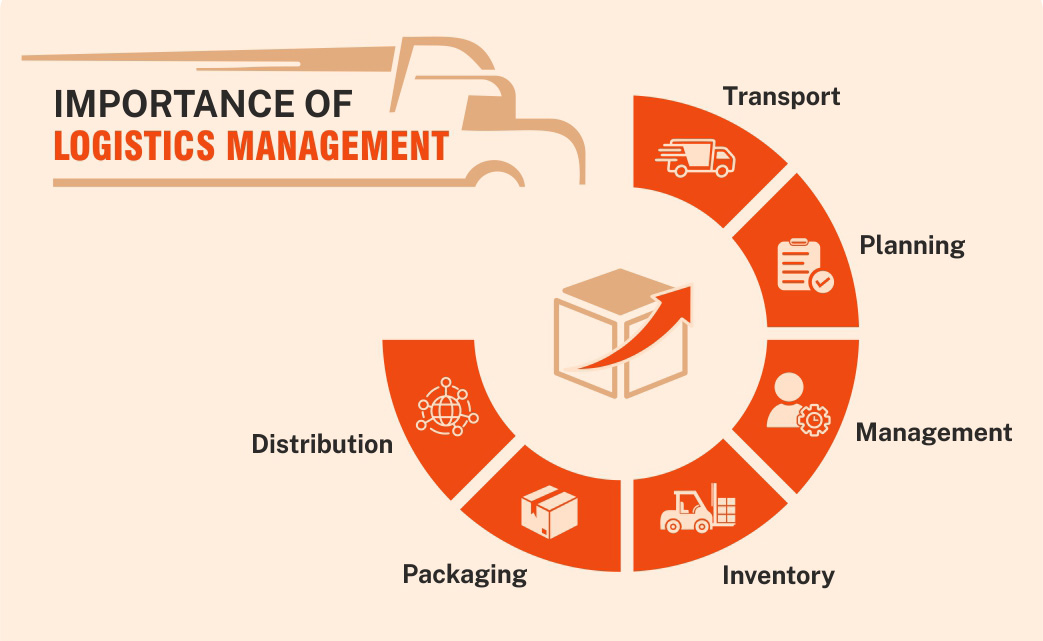

Importance of Logistics Management: Why and How it Benefits Your Business?

Ever wondered how the pair of shoes you ordered yesterday afternoon arrived at your doorstep this morning? Or how your local supermarket is always stocked with fresh produce, no matter the weather conditions or any other factor?

There is no magic behind this. This is the work of logistics management, the invisible system that keeps our world moving. It is the silent engine that powers our global commerce. Behind every seamless delivery, every stocked grocery shelf, and every product that is purchased online and delivered is an intricate web of planning, coordination, and execution known as logistics management.

How important is logistics management?

A study by Accenture found that supply chain disruptions caused companies to miss 7.4% – 11.0% revenue growth opportunities. McKinsey found that 80% of companies consider logistics and transportation to be a key driver of business success.

In a nutshell, logistics management can break or make a business and can significantly dent its revenue numbers. So skim through the world of logistics management and understand how you can optimize your logistics management to make your business more efficient, the factors that affect logistics management, and the importance of logistics management.

What Is Logistics Management?

In simple terms logistics management is the process of planning, executing and controlling the flow of any commodity from one place to another place. Logistics management is responsible for a product/commodity/package to be at a certain place at a certain time in a certain quantity and condition.

At a deeper level, logistics management is about keeping all factors in sync and ensuring there is no disturbance in the system and the product moves from one phase to the other smoothly.

Logistics management can be compared with the conductor of an orchestra. It ensures all instruments—manufacturing, transportation, warehousing, inventory control- are working in perfect order. Logistics management ties all aspects of the process together and prevents any breakdown of the system.

Difference between logistics management and supply chain management

If you have followed this blog till here, the term ‘supply chain’ would have definitely popped up in your head. The terms ‘logistics management’ and ‘supply chain management’ are often used interchangeably, but they are remarkably different from each other.

Supply Chain Management is the umbrella term. It is used to refer to all activities involved in manufacturing and delivering a product or service. It includes but is not limited to, sourcing raw materials, manufacturing and distribution.

On the other hand, logistics management is one of the arms of supply chain management. It deals with the movement, storage, and delivery of goods.

8 Top Benefits of Logistics Management

-

Drop costs :

A key aspect of logistics management is to analyse every part of the process and to enhance its efficiency. Logistics management scouts for any discrepancy or ineffectiveness and weeds it.

Logistics management keeps all processes in sync and brings the best out of every system. This helps in reducing the costs and moving things faster. An efficient logistics thus helps you keep your overall product cost in check.

-

Better visibility :

An interesting benefit of logistics management is overall better visibility in supply chain management. Logistics management makes it possible to scrutinise every step in the supply chain. This in-depth monitoring of goods from development to storage and to final delivery to customers helps in offering timely delivery.

-

More customer satisfaction :

As per a study done by PwC, 32% of customers said they won’t shop with a retailer after just one bad experience, including late deliveries. This stat highlights the importance of offering timely deliveries and this is exactly what efficient logistics management helps you to achieve.

With efficient logistics systems in place, you can meet delivery timelines. This means more happy customers and more repeat orders.

-

Reduce overhead costs :

Logistics management sheds light on some important areas such as understanding how much warehouse space is actually needed. By understanding these statistics, companies can shrink their warehouse space and thus end up reducing overhead costs.

-

Risk mitigation :

'If identified earlier, a risk is an opportunity.' This famous quote undermines the importance of finding out possible risks in time and logistics management helps you do that exactly the same.

It helps in identifying the possible risk in delays, thefts and compliances. By having a proper buffer and plans in place, it becomes easy to counter the unforeseen circumstances and navigate the challenges.

-

Sustainability and environment responsibility :

Any responsible organization is aware of its impact on the environment and is constantly seeking ways to reduce any negative impact. This also helps in building a brand image as customers are generally happy to shop from a brand that thinks about protecting the environment.

With proper logistics management you can end up reducing fuel consumption and carbon emissions.

-

Gain competitive advantage :

Delivering goods on time has enormous benefits. In B2B and B2C businesses having the ability to deliver on time and accurately again and again is a big muscle flex. Logistics management enables you to enjoy that ‘X-Factor’ that differentiates you from the other players in the market.

-

Supports expansion :

Logistics management helps you to calculate inventory needs, stocking requirements and other aspects in an accurate manner. This invariably helps in scaling up and delivering more orders on time.

The 7 R’s of Logistics Management

The Chartered Institute of Logistics & Transport UK (2019) has given a definition of 7 R’s of Logistics Management. It says, " Getting the Right product, in the Right quantity, in the Right condition, at the Right place, at the Right time, to the Right customer, at the Right price." These seven R’s form the pillars of efficient logistics management. Getting them right is crucial for having an ideal logistics management system.

Let's look at these seven R’s in detail:

-

Right Product :

This may sound like a no-brainer that when supplying a product to a customer, the company should ensure that they are sending the right product. But when you are shipping thousands of products on a daily basis, mistakes can happen. And this is where right logistics management policies come in as savior.

For example, Apple has spent considerable resources to ensure when a customer orders an iPhone with specific storage capacity and color, the exact model is sent to them

Similarly, a company can be proactive and make the logistics management smoother by designing the product in a specific manner. This practice is known as ‘Design For Logistics’. For example, Coca-Cola manufactures 12-ounce cans and 2-liter bottles in a specific design. These designs fit perfectly on pallets and in vending machines. These stackable designs maximize the use of truck and pallet space, ultimately reducing the number of trips needed.

-

Right Quantity :

Imagine walking into your nearest grocery store only to find out the item you are looking for is sold out. Now imagine this happening again and again. At one point you will run out of patience and will decide not to visit the store again.

This is the exact reason why companies ensure they deliver not only the right product but also deliver it in the right quantities as it can affect the enter system. Walmart uses predictive analytics and demand forecasting to figure out which product to put up in which quantities in the stores based on the seasons and holiday seasons.

-

Right Condition :

Right product in bad condition is equal to wrong product. Imagine you order a product, then excitedly track it till it gets delivered. Then unbox it with plenty of anticipation and then find out that it's damaged. What do you do next?

Of Course the company collects the damaged product and sends you back a replacement. But nothing can compensate for your disappointment and the time you lost in the entire process.

This is why, as an organization, it is important to prioritize delivering the product in the right condition. An efficient logistics management arm will understand the requirements of the products and will design a transport system that keeps the products safe and secure during the transit process.

-

Right Time :

A key factor driving the success of Domino’s pizza is its unique ‘30-minutes delivery’ feature. The famous pizza chain leverages GPS technology, real-time route mapping to deliver their products at the right time.

It’s not just about pizzas. Not delivering the product at the right time is as good as not delivering the product at all. Hence, companies must plan their logistics cycle in such a way that it meets the delivery timelines and has enough room to handle any unforeseen delays.

-

Right Place :

If the package is not delivered at its designated destination it disrupts the entire logistics chain. The package then needs to be picked up from the wrong location and needs to be delivered again. This means one wrong action requires two additional actions. Hence its paramount to have systems in place that ensure the product reaches the right destination every single time.

-

Right Cost :

Amazon upped the e-commerce game for all competitors by offering ‘free shipping’ on its products. This made a heavy impact on customer’s minds and affected their decision-making. Amazon was able to pull it off as it cracked the logistics challenge. Amazon used efficient logistics planning and created a system that reduced costs and enabled them to ship more products in less time and money.

An efficient logistics chain that reduces the costs of shipping goods is detrimental to your company’s success. You not only gain a competitive advantage but also can become a customer’s preferred choice if you are able to ship the products at the right cost.

-

Right Customer :

When you are shipping thousands of products on a daily basis, it is important to ensure you have 100% accuracy in delivery. From B2B to B2C, the cost of a wrong delivery is enormous.

Thus, it is vital to have a process in place that ensures the right delivery every single time. Imagine a restaurant ordering bakery items for its breakfast menu but the supplier sends it to the wrong restaurant. This will affect the operations of the restaurant significantly as they will fall short of delivering breakfasts to their customers. Similarly, the other restaurant has to go through the unnecessary headache of asking the supplier to take back the order.

Logistics Management Flow Chart

A logistics management flow chart is a way to explain the entire logistics process in a simplified manner. It is the visual representation of the entire process.

These are well-defined, documented, and reviewed charts created to achieve cost-effectiveness and achieve all the prescribed goals.

The main components of the logistics management flow chart are.

Warehousing

Warehousing includes managing, receiving, picking, storing, and loading orders for delivery. Logistics management flow charts are effective for warehousing operations as it brings in more efficiency and reduces errors.

Transportation

Logistics management flow charts can help in managing transportation effectively. Transportation is the vital cog for the functionality of ecommerce business. It becomes easier to have proper maintenance of transport vehicles such as trailers, cars, trucks through effective flow charts.

Planning delivery routes, timelines becomes hassle-free if transport vehicles are always in the best working condition and free of any repairs.

Delivery

The final nail in the coffin in the logistics cycle is the delivery process. Often known as the ‘last-mile delivery’ it is the phase when the shipment is sent from the warehouse to the customer’s address.

This part is a crucial step and involves several complexities. A logistics management flowchart improves the delivery operations as it helps the stakeholders to map out all decision points and makes it easier to process them.

Now let's look at some of the key benefits of these flowcharts:

Now let's look at some of the key benefits of these flowcharts:

- Improved Visibility: A flow chart displays all processes and steps properly. This helps the decision-makers to quickly understand the process properly and have a look at the important touch-points.

- Increased Efficiency: Flowcharts are a great way to Identify the current and possible bottlenecks that are existing or may exist. Businesses can also discover other opportunities for process improvement.

- Reduced Costs: Flow charts help in optimization of logistics operations which leads to cost savings.

- Improved Customer Satisfaction: With better understanding of the process, comes more efficiency. Thus, flow charts invariably help in achieving delivery timelines and delivering more shipments in less time. As customers receive their products in quick time, it results in enhanced customer satisfaction.

Conclusion

Logistics management is the cornerstone of a successful business. Any movement of goods requires resources. These resources include time, human labour, money and other resources.

Logistics management is about monitoring, controlling, executing and improving this chain of activities that result in delivering goods from one place to another. If not done properly, the goods can reach late, or can consume more resources for the movement. At worst, the goods may not even reach the destination.

The implications of these inaccuracies are enormous. It may cause financial loss, kill customer trust, hamper brand value, affect profitability and ultimately would eat up your business.

Hence logistics management is paramount for the wellbeing of any business. Thus, you should always seek to make your logistics management efficient. For this it is advisable to seek help from expert logistics provider companies that have good experience and market knowledge.