- GF/ SF - Tejas, Opp Hotel Prasadalay, Shukrawar Peth, Pune - 411002

- +91 90 2132 2132

The Power of Capacity Planning in Supply Chain Management

Are you finding it difficult to maintain stock shortages or excess inventory? You are not alone. Many businesses find it challenging to balance supply and demand. That’s where capacity planning comes into picture. It helps a business in the smart utilization of resources, forecasting, as well as operating efficiently.

In today’s fast-changing market, good capacity planning isn’t just an advantage - it’s a necessity. So Let’s get started.

What is Capacity Planning?

Capacity planning in today's quick-moving markets balances supply and demand for your business. When it comes to supply chain management, capacity planning is a game-changer. If capacity planning is efficiently utilized, it helps access limited resources with the aim of improving forecasting, inventory control, and cost efficiency.

But this is only the beginning. Smart capacity planning can lead to faster lead times, improved customer satisfaction, and brand-new operational agility. This way, you’re not just keeping up with today’s market also you’re staying ahead and building a supply chain that’s ready for the future.

Why Capacity Planning is a Game-Changer for Your Supply Chain

Capacity planning is not only about managing resources but also about creating a smarter supply chain. Here’s how it helps businesses stay ahead:

- Improves Customer Service – Meets demand by ensuring the right products are available at the right time.

- Lowers Cost – Avoids unnecessary costs by looking into capacity requirements, which helps in optimizing resource allocation.

- Optimized Inventory Levels – Appropriate inventory levels meet the present and future demands through real-time alignment of the supply with demand, thus avoiding overstock and understock situations.

- Faster Response Times – Responds quickly and reverts to market changes and customer needs to improve lead times and reliability.

- Reliable Service Levels – Reliable services with respect to delivery time and order fulfillment management through the preemptive handling of capacity constraints.

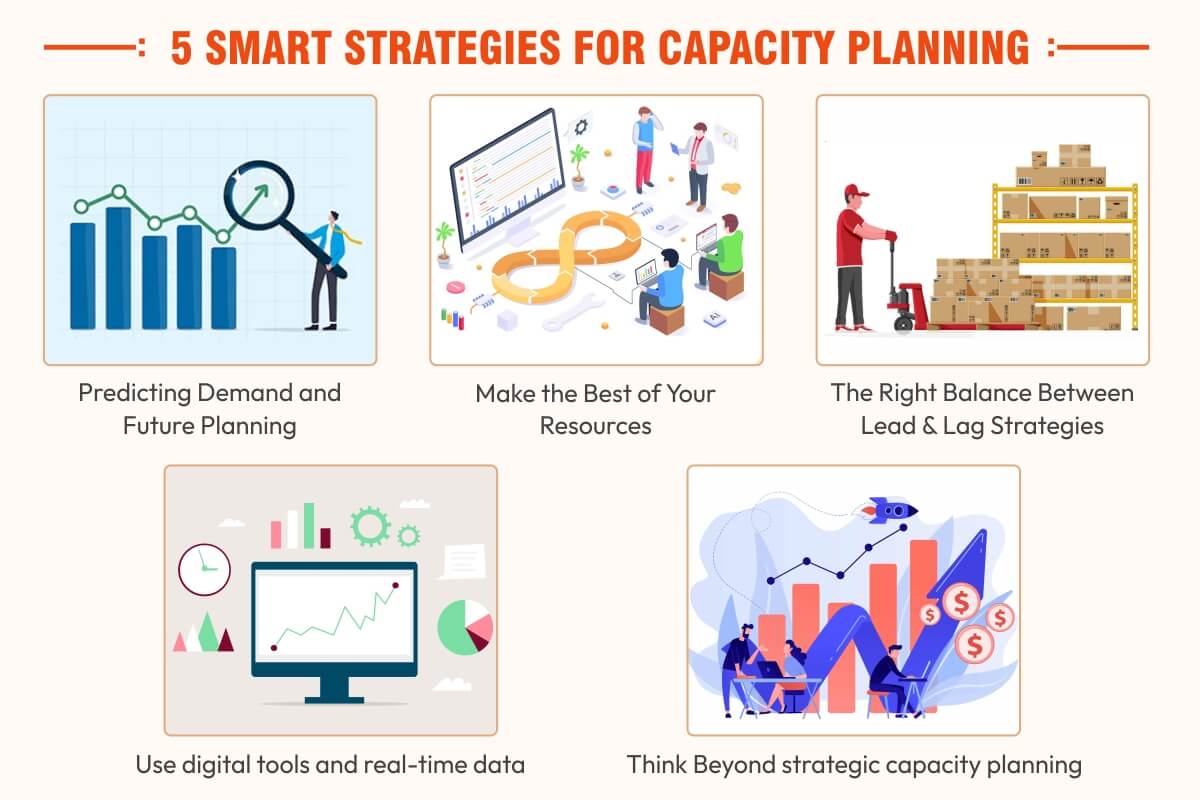

5 Smart Strategies for Capacity Planning in Supply Chain Management

-

Begin with Predicting Demand and Future Planning

Capacity planning begins when you know what your customers need and when they need it. That’s where demand forecasting comes in. Using available data, forecasting trends and planning resource allocation will commence.

For example, certain products sell more during festivals, so in that case, you can increase production ahead of time. This helps you avoid last-minute shortages or having too much stock when demand drops.

Demand Forecasting also allows you to consider alternative backdrops such as best case, worst case, and everything else in between. With a flexible strategy, you will be prepared irrespective of changes in demand. Check out this blog to read more on Demand Forecasting.

-

Make the Best of Your Resources

A major part of capacity planning is using your resources wisely. This includes machines, materials, and your working team. If they are not used efficiently, costs go up, and profits take a hit.

For example, on some routes, vehicles may be operating at half capacity for a company. Instead of wasting fuel and raising costs, they can combine shipments, adjust schedules, and keep trucks full. This cuts costs, improves efficiency, and gets deliveries to customers faster.

The goal is to do more with what you have without overloading your team or equipment.

-

Find the Right Balance Between Lead and Lag Strategies

In capacity planning, you will come across two main strategies: lead and lag.

In a lead strategy, one increases the capacity in advance of the expected demand. It helps you be on your toes when the customers come to need your product. For example, a company expecting a festival shipping rush might hire more drivers and more delivery trucks ahead of time to ensure smooth and timely deliveries.

A lag strategy means postponing capacity expansion until demand rises. It allows the elimination of unnecessary costs. However, it also carries the risk of not having enough capacity in time to meet demand if a sudden spike occurs.

Now, which is the best approach? A mix of both. Balancing lead and lag strategies helps you scale efficiently without overspending or falling behind.

-

Use digital tools and real-time data to boost capacity planning

In the real-time space, data helps you track production, monitor resources, and instantly adjust plans. Observe changes in demand through AI forecasting tools and edit the schedules accordingly.

Automated repetition would allow your team to focus more on their high-priority work duties while ultimately increasing efficiency and productivity without breaking an extra sweat.

Stay flexible, make data-driven decisions, and keep operations running smoothly.

-

Think ahead with strategic capacity planning

It's not only meeting today's demand – it is preparing for growth. If you intend to enter new markets or launch new products, ensure that your capacity grows with demand.

This may include expanding facilities, upgrading technology, or changing production methods. Long-term planning keeps you in front so you can anticipate rather than react to changes.

Wrapping Up

Plan wisely, adapt quickly, and set your business up for long-term success. Capacity planning is not only for survival but also thrives in competitive markets. You can enhance your savings through strategizing, increased efficiency, and better customer satisfaction.

Start implementing these best practices today and build a supply chain that’s ready for the future.